Snap fits (also known as Clip Snaps) are moulded plastic features of products which clip two parts together. You have probably seen them, in various plastic products before, but you may not have realised how much thought and effort goes into getting these right. Plastic Snap fits are used to assemble plastic parts together with the need for additional (and sometimes costly) fasteners, like screws and bolts. Essentially, snap fits are a hook shaped protrusion that indexes with a corresponding depression, usually being able to come undone if you can flex the arm again. We’ll run through the 4 basic types of snap fits, and the advantages and disadvantages of snap fits in your injection moulded product.

There are four basic types of snap fits, and these are Cantilever snap fits, U-Shaped snap fits, Torsion snap fits, and finally Annular snap fits.

Cantilever Snap Fits are essentially locking lugs on arms that can flex. These fit into corresponding holes, which have a retaining lip to prevent the arm from sliding back out again. Cantilever snap fits are used just about everywhere in plastic design though you might not notice it. Chances are that there is a cantilever snap fit cover in your car’s engine bay covering up the fuse boxes or clipping a electrical terminal together.

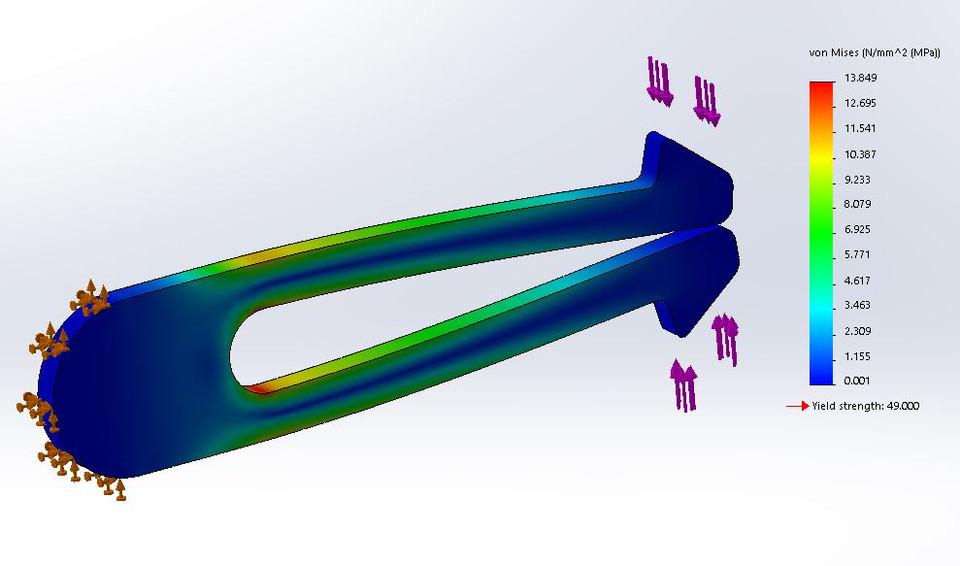

U shaped snap fits are very similar to cantilever snap fit, just imagine it bending back on itself. It does this to provide and in built hinge point rather than rely on a cantilever pivoting point. These types of snap fits are usually find in applications where the parts need to be pulled apart again and again or where the contents of the two parts don’t require a lot of force to stay in position. For example, a lot of remote controls have a lid on the battery section, and this lid is often held in place with a U-shaped snap fit.

Torsion snap fits use shear stresses to move the arms in and out of position, so that the clips are on the side of the opening. Think of the shape of the clip being like a clothes peg. When you depress the levers the pegs open, but when you let go the peg closes again.

Annular (meaning ring shaped) clips snaps are a clip snap that goes around the perimeter of the product and locks into place. Annular snap fits are very common too, but are again often over looked. A pen with a lid that clips onto it has a very small annular snap fit, which keeps the lid in places. In addition to this, a lot of tubing and piping products have annular snap fits , to seal the entire perimeter of the tube with ease.

So know that you know the common snap fits, what are the pros and cons of using snap fits on your part?

The perks of having snap fits are:

- Easy assembly – the parts just clip together.

- Less unit cost (as you don’t have to buy, over mould or insert fasteners).

- Improved aesthetic

- Fewer Moving parts – reducing overall product complexity

- Cheaper than other forms of fastening.

The downsides are:

- If they break, you must replace the whole part.

- Can be difficult to disengage.

- Are perceived as a cheap product feature.

- May cause undercuts in your plastic parts.

- They are difficult to prototype (most prototypes aren’t made in the material they are moulded in).

So if you’re on the fence about how to fasten your plastic parts together, come in for a free-zero-obligation meeting or contact us via our website.

Subscribe to Our Newsletter

Get the latest news from Dienamics into your inbox