Radii or Radius, is a technical term that we often throw about the office – but this series is about deciphering jargon, not glorying in it, so let me explain it here. Radii are used to describe a smooth transition between two lines in a 2D sketch or technical drawing. When we turn a 2D drawing into a 3D object the proper radii ensure the surfaces that those lines represent also have a smooth transition. Once the feature exists in 3D, it’s called a fillet. Now these radii and corresponding fillets are critical because they play a huge role in how products are made and how they function.

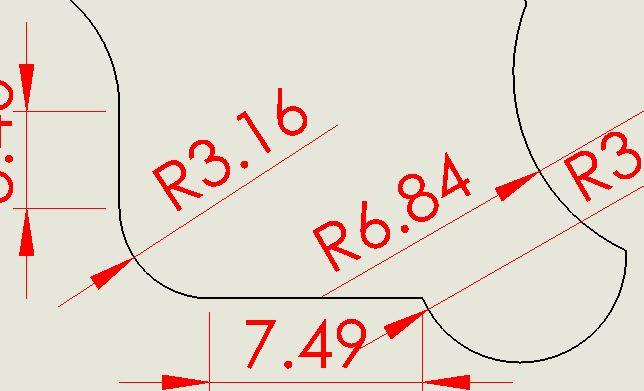

A radius is exactly half the diameter of a given circle and is noted on design drawings and sketches with a prefix of “R”. Say you have two lines joining each other and you want a smooth intersection, you would draw in a curve and note that as R 5.50mm, for instance. The bigger the R value, the bigger and smoother the resulting curve would be.

Now that we’re on the same page about what radii are and how to describe them on 2D sketches, what’s next? Well now that we have your design or idea down on paper we need to make a 3D computer model (aka CAD Model). A lot of manufacturing is performed by computer driven processes, and 3D models are the language they speak. In creating your 3D Model we’ve taken all the radii and turned them into fillets. Why? Well that’s because it’s no longer just a section of a 2D circle – we’ve made it 3D; however, it’s still uses the same dimension. You can say that this 3D curved surface (aka fillet) has a radius of R5.50mm – that makes perfect sense to us.

So why is it important to have radii? Well let me just stop and tell you that every single plastic part has both radii and fillets. You cannot escape them. They might be tiny, 0.05mm for instance, but they are there. And that’s because it’s poor practice to make surfaces that meet in perfectly corners when you’re making a plastic injection mould. During moulding sharp edges do not like ejecting cleanly from the mould, which will increase your cycle time (and cost!) and also leave furry corners on the product. And in most cases, it’s better for the parts lifespan to have radii and fillets because when products that have two surfaces meeting at an intersection, that intersection becomes a stress point which can rip, shear or bend. Putting in a fillet or a radius means that the part may have more of a chance to deflect or absorb the forces acting on it.

Subscribe to Our Newsletter

Get the latest news from Dienamics into your inbox