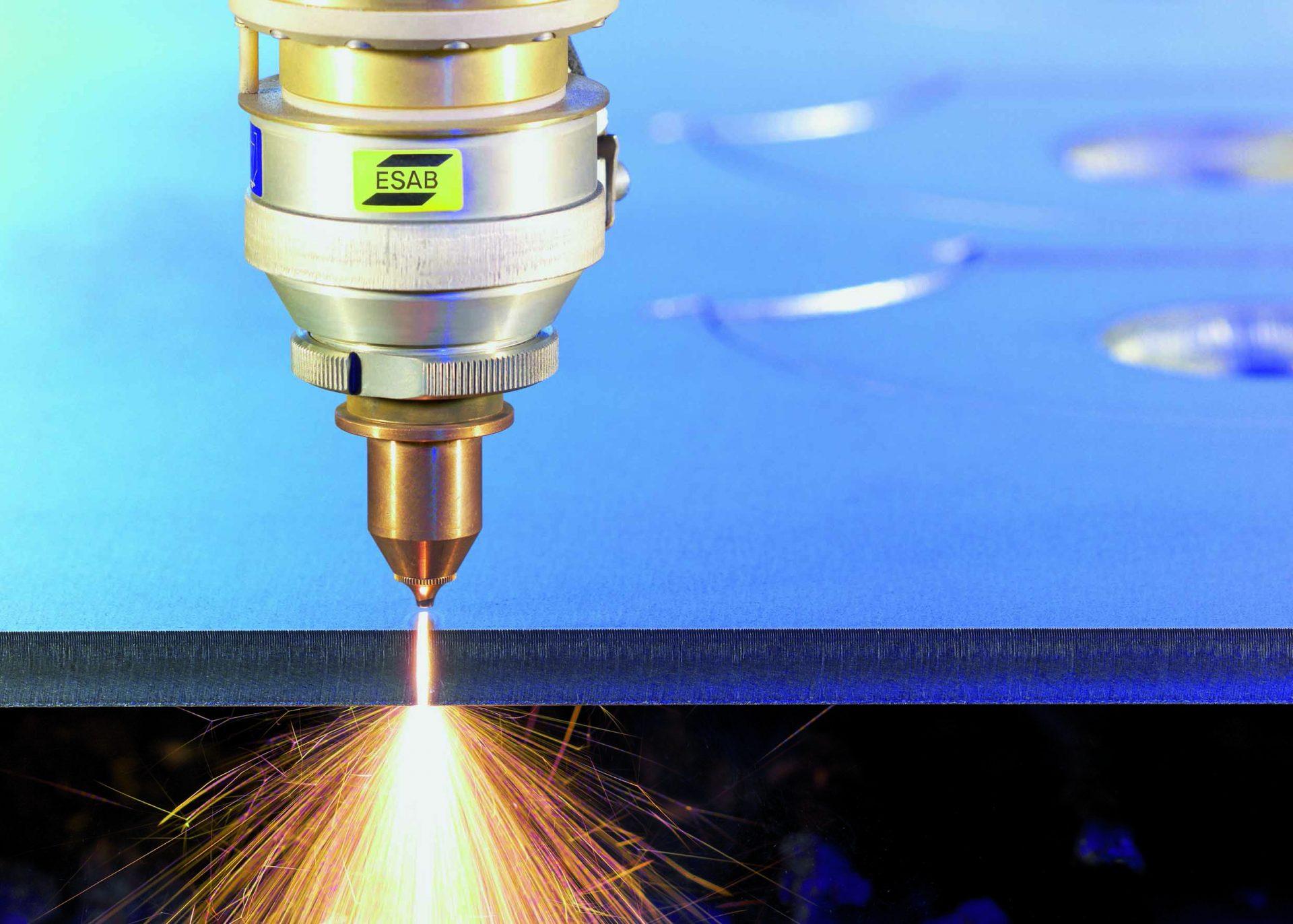

Laser Cutting – you’ve heard of it or know someone who has, but what is the actual process of laser cutting? Well it uses a super-hot beam of light to melt, burn or vaporises stock material. In certain machines, laser cutting can produce anything from structural welds, clean cuts and even up to very fine detail etching. In this article, we will cut through the jargon and explain the laser cutting process and considerations, the benefits and disadvantages to getting products laser cut.

As a side note, there is also a form of Laser Machining which uses a multi-axis head to do detail machining with the laser cutting process. How do we know all this? We often machine laser cut parts and one of our clients relies heavily on laser cut steel parts, which is all done in house, in our toolmaking workshop.

Laser cutting is another way to form products that can be made from sheet materials. Sheet metals, woods, even paper, leather and ceramics can all be cut by laser. The basic process is that an operator feeds sheet material into a cutting bed and the laser is travels back and forth over the piece being controlled by a computer, from a CAD file. The laser is a highly focused light, which creates a lot of thermal energy and this energy cuts, welds or burns the material.

However there a few drawbacks you should know before creating a laser cut product. The scale of products is limited by sheet size, and also by the size of the machine. Having said that the detail level of cuts can be as fine as 0.025mm diameter holes, which is incredibly fine. You should also be aware that certain metals have a high rate of thermal conductivity and will need longer time or a higher-powered laser depending on the machine. Also, highly reflective materials deflect the focused laser beam causing them to either not be affected, or be affected only marginally by the laser beam.

The benefits of laser cutting are:

- Laser Cutting produces a consistent high quality and accurate cut.

- There is little to no clamping of the sheet material

- Suited to a range of sheet type materials, (metal and organic materials)

- Laser Cutting Machines require little to no maintenance due to the limited contact with the stock material.

The disadvantages of laser cutting are:

- Thick sheet material can cause problems in cutting and it is better to cut the same profile repeatedly than to increase the power of the laser.

- Laser cutting is a time-consuming process in comparison to process like sheet metal forming. It’s best to use laser cutting for one-off pieces or small batch and runs.

- Laser cutting is highly energy intensive, so if you invest in a laser cutting machine expect an increase in your electricity bills.

- Sheet material wastage is often high.

- Generates vaporised particulate gases, which need to be vented safely.

If you’re unsure about your product design and whether laser cutting is right for you, contact us for a free, no-obligation 1 hour meeting with our design team.

Subscribe to Our Newsletter

Get the latest news from Dienamics into your inbox