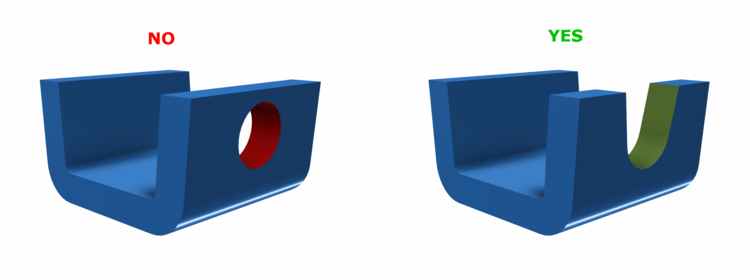

Undercuts. No Plastic Injection Moulder wants them and every DIY part design has them. Undercuts, are part and parcel of what we do here at Dienamics. Most of our clients are looking to create or improve their own products, but are restrained to a strict budget. So, one of the first things we look for in an injection moulded part, is whether the part has an undercut. An undercut is a surface or face that can’t be formed by either the core or cavity in an injection mould tool. Having in-house Part and Tool Design experience is a huge help in avoiding undercuts in the first place.

Usually the first thing we do when we see an undercut is try to remove it. We do this because we aim to run your tool as efficiently and economically as possible. By removing the undercut, we would allow the part to run in what we call an Open-and-Shut tool. These tools, as the name suggests, open when the part is being ejected, and close for the next shot. This minimizes cycle time which means that your unit cost is driven down to the minimum.

If the feature can’t be removed, or is critical to function in a certain way which forces us to retain the undercut, we may suggest moving the parting line of the product to the middle of the undercut. This could be as simple as dipping the parting line down in certain spots or you might end up with a parting line that zig zags across your part. Not only does this look bad, it makes it difficult to create your tool. We might also have to move where your product is gated. This affects how the plastic flows through your part and may cause undesirable results.

If the design is absolutely set in stone, and there’s no other way of making your product then there are a few ways to create tooling that makes the feature. From least to most complex and costly, there are 4 main methods:

- You can use sliding cores.

- You can use rotating cores

- You can use sprung cores

- You can use collapsible cores

Sliding cores, slide straight into position, usually at 90° degrees from the line of draw. These require the least amount of machine and tool design as they are usually of a constant cross section and move in just the one direction.

Rotating cores are like sliding cores as they only move in the one direction, but rotate whilst doing so. These are the most common types of cores when it comes to forming threads in plastic.

Sprung cores are bent or angled pins that form part of the cavity wall. As the tool closes they are fixed into position, and as the it opens, they spring out of the way of the part being ejected.

Collapsible cores are yet again more technical and expensive being made up of a series of shapes that can fit through a small opening. Once in the correct position, an actuating rod pushes out sectors of the collapsible core to form the undercut. The part is then moulded around it and once cooled the collapsible core collapses again and retracts before the part is ejected. If you need help with undercuts and want to know more about your plastic part design, come in to our design office for a free, no obligation 1 hour meeting.

Subscribe to Our Newsletter

Get the latest news from Dienamics into your inbox